Written by Dr. Alexander A. Schuessler, SmartEquip's Founder & President of International Group.

Published in Lift & Access, January - February 2020.

In early 2000, a new type of technology platform began its gradual, long, disruptive shift across the global equipment industry with regard to the electronic distribution of parts and service support information to equipment owners. And while today, two decades later, the use of such technology has gained a universal footprint – approximately 500 suppliers to the equipment industry are actively using such a platform to support roughly 50,000 service technicians and parts purchasing professionals around the globe – it is a little-known fact that the solution first gained use among North American manufacturers of access equipment and their customers.

Previously, in the late 1990s, manufacturers like Genie, JLG, and Skyjack had begun to distribute parts and service information via newly created websites, alongside initial parts e-commerce capabilities. Support documents were offered in electronic form to replace the distribution of service information via printed books and microfiche, and e-commerce platforms were offered to replace the ordering of parts via phone and FAX. Yet initial adoption by users of web-based service and purchasing was slow, even as more suppliers followed suit and created service portals and “web shops” for parts. Paradoxically, as manufacturer support and e-commerce websites sprouted up, it became increasingly difficult for fleet owners to use them: service technicians had to remember a growing number of usernames and passwords, as well as master an expanding set of rules on navigating the ever-growing set of websites. And once they placed orders via these sites, they had to re-enter purchasing information into their own systems to create work orders, purchase requisitions and/or purchase orders. From the perspective of customer efficiency during this period, the initial move from “paper” to electronic “glass” was a step toward inefficiency.

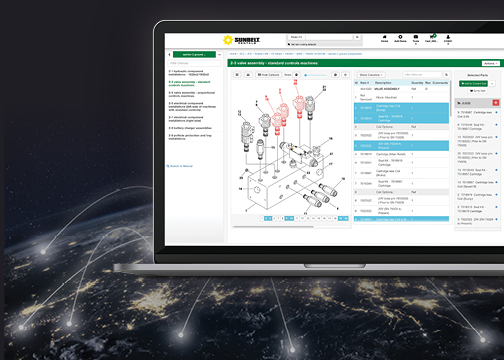

Starting in 2000, however, and beginning with manufacturers of access equipment, the use of intelligent service support and parts procurement technology no longer required manufacturers to wait for their customers to come to their websites to access support information. Instead, they could now actively pinpoint-deliver service information into the fleet management systems of equipment owners. In real time, they could “inject” dynamically customized, serial-number-specific interactive parts diagrams and service manuals directly into the workflow of technicians working on specific machines. This resulted in significant increases in “wrench time”, as service technicians no longer chased information across hundreds of external systems via websites.

With regard to ordering, similarly, technicians selected the parts they needed for their service or repair via interactive parts diagrams, and the system would now auto-generate and -populate work orders, purchase requisitions, and purchase orders with zero manual effort, and then electronically submit this information into the systems of their suppliers.

And finally, because both manufacturers’ and fleet owners’ systems were connected, pricing information was always in synch and “item master” information on fleet owner systems became self-updating. This significantly decreased the workload of personnel in both accounts payable and data maintenance.

Why do we care so much about parts?

Providers of “integrated service and procurement” technology are often asked why they care so much about parts, especially as parts only reflect about 1.5% of a fleet owners total spend each year. For starters, parts purchasing is both the most frequent and most complicated form of buying they do. Typically, more than 85% of the orders they place in a given year are for equipment parts, and identifying the right part without intelligent electronic support is difficult and error prone. moreover, these errors instantly translate into an increase in machine downtime.

A far more interesting reason for why we care about electronic parts-based solutions, however, are the massive improvements they bring in the form of labor savings and equipment uptime.

The typical equipment owner spends approximately 3% of its fleet’s original equipment cost (OEC) on parts, and another 3% on service labor. Adding an electronic solution to parts purchasing will drive down both types of cost: through spend control, it will ensure that the right part is bought at the optimal price, and through intelligent distribution of support information it will also eliminate the search for manuals, the need to manually fill work orders and purchase orders, thus leaving technicians much more time to focus on their work. Most remarkably, while spend control may reduce parts cost by 10-15% (or 0.3-0.45% of OEC), the effect on service labor time savings will be far more pronounced, potentially in the greater-than 50% range (or 1.5% of OEC).

In addition, another 0.75% of OEC jointly incurred in the form of accounts payable (AP) costs and master data administration are eliminated, because pricing is automatically synchronized, and fleet owners’ item master files are automatically updated when manufacturers change or offer new parts.

And, finally, in terms of uptime, each hour saved in the repair process results in an additional hour of machine availability. Users of integrated service and parts procurement technologies frequently claim the benefits associated with machine availability gains alone to be greater than total benefits from parts cost and labor cost reduction taken together, implying a more-than doubling of the initial cost savings.

So why do we care so much about parts technology? Not so much because of the total 0.3 - 0.45% in OEC they may save us on parts spend, but because of the roughly 3 - 6% in OEC they can generate in service labor, back office labor, and equipment uptime improvements together.

Table: Relative improvements on parts, service, back office costs and fleet uptime via electronic procurement platforms.

“Surely this cannot work for me?”

In the early years, integrated service and procurement solutions used to be available only to large enterprises – no longer. Much like Salesforce has brought customer relationship management (CRM) into the “cloud” and is offered as a software-as-a-service (SaaS) solution, parts procurement and service management solutions, too, are now available on a subscription basis, requiring no purchase of hardware or software.

Next time you wonder whether the best way to save on your fleet is through negotiating better equipment pricing or looking for alternative parts suppliers, consider that the answer may lie entirely elsewhere. Does your manufacturer offer the technological means to shift the operating efficiency of your business in this far bigger way? Thankfully, in the access equipment industry, for most of your suppliers the answer has long been “yes”.

Figure: Fleet owners like Sunbelt Rentals have long relied on integrated service and parts solutions to provide operational efficiency improvements across parts, service, and back office labor and improved equipment uptime.

Dr. Alexander A. Schuessler is the founder of SmartEquip and president of its International Group. He is also a member of the technology committee of the European Rental Association.