Source: RERMag.com

Lightning-fast speed. Easy e-commerce capability. Real-time performance monitoring. Social media transactions. Business intelligence on demand. YouTube channels. Thorough online training. Increasing uptime and wrench time. Business modeling for the future. Servicing from remote locations. These are just a few of the things that rental companies need in 2014, and just some of what software suppliers are offering. Every year, newer and better programs are available, and we do our best to keep up to date.

The list in the full article covers multiple providers. SmartEquip portion is below:

Increase Uptime with Streamlined Parts Ordering

What is the most important purpose of a service technician? Is it searching through manuals to find part information? Is it after, hopefully, finding a part number, getting on the telephone and ordering that part? And if that part has been superseded by a newer part, would it be arranging to send a part back to the manufacturer and trying to find the correct name and number for the part?

Not likely. The most important task for a service technician — who with most rental companies these days, especially if they are well-trained, certified, experienced and accomplished, make a pretty good salary – is to spend time actually working on equipment. However, with many rental companies, it’s certainly possible that service techs might spend 30 or 40 percent of their time doing something else, rather than actually fixing equipment. And consequently, many rental companies have far too many machines in the shop awaiting service. Equipment not working is downtime, not making money, not contributing to ROI.

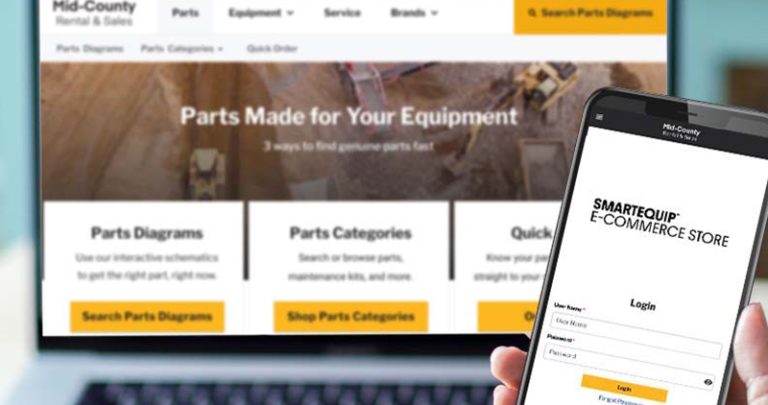

With SmartEquip technology, a rental company’s percentage of uptime can increase dramatically. The service manuals are now online and constantly updated by the more than 130 manufacturers that are part of the SmartEquip network. When parts and service information is updated by the manufacturer, the rental company has to do nothing; it’s all done automatically. And in most cases, the part the technician is seeking is represented visually through schematics, and with a few keystrokes, the service technician can find the part he needs and order it to be sent immediately.

SmartEquip Reaches Small & Mid-Market Companies

For several years, the SmartEquip network was primarily the province of larger rental companies that, through economies of scale, could make the program – which integrates with rental management systems – cost effective. SmartEquip has, in the past year, developed a new module to make the system effective and affordable for smaller, mid-market rental companies.

One such rental company, which has benefited from SmartEquip for several years, is Rental One, based in Fort Worth, Texas.

“In the past, prior to SmartEquip, a mechanic would spend a lot of time trying to research and find out what the right part was in conjunction with our parts department,” says O’Neal. “They would order the part and not realize it was superseded by a new part, so when the wrong part came in, we would have to turn around and send it back to the manufacturer to get the right part. That’s been eliminated with SmartEquip because it knows if anything has been superseded and automatically does it for you. It knows our inventory. I don’t think we’ve had a mistake in parts ordering where we ordered the wrong thing, that problem has been eliminated. We used to have a huge inventory of parts, a lot of dollars spent. Now we have what I’d call a parts closet. We only keep the bare essentials like filters, because the process of ordering is so simple. And our mechanics can do what they are supposed to do – turn wrenches and fix equipment. Our uptime is through the roof.”

SmartEquip has enabled the mid-market rental companies to similarly streamline training systems and other data entry operations. SmartEquip founder Alex Schuessler adds that the data management benefit is even greater than he’d anticipated.

“Companies are telling us that data management is a manual process in which they’re constantly behind, which is to upload and manually type in these constantly changing lists of numbers,” he says. “We’re writing it into their system at the time of order and they are immediately integrated into their system. So the parts order goes right through and is fulfilled more quickly, which again reduces downtime.”