We are under one year away from CONEXPO-CON/AGG 2023. It’s been an unusual stretch of time in the three-year gap between shows. The world shut down (quite literally) in the days following the show in 2020, and the last two years have been overwhelmed by the pandemic.

The good news: The North American construction market is strong. The backlog of work shows no signs of letting up and a forecast of positivity is already starting to spread deeper into 2023. Global construction forecasts are just as bullish, with some, seeing the market doubling between now and 2030.

It’s a fascinating time to be part of digitization within the construction industry. And it’s a growth curve that will challenge how equipment owners will buy, manage and support their parts and equipment inventories. Continuing supply chain challenges, access to parts and extended equipment life cycles will evolve how we manage fleets, both large and small.

With the lead-up to CONEXPO 2023, the industry will be inundated with new product launches, shiny widgets and a wave of new concepts and solutions — some practical, and some that will never see the dirt of a jobsite.

Here are some things we’re tracking that we believe will impact the industry in the next year:

The Digitization Will Continue

Telematics. Remote diagnostics and software updates. Apps. Blockchain. The proliferation of connected technology that leverages data and intelligence from heavy and compact iron will continue as a fleet management tool, as a business guidance tool, and as a job/productivity enhancer. The information provided by sensors, connected telematics systems and other technologies will continue to evolve how we look at fleet management and shorten the time and distance between the identification of an issue and its resolution.

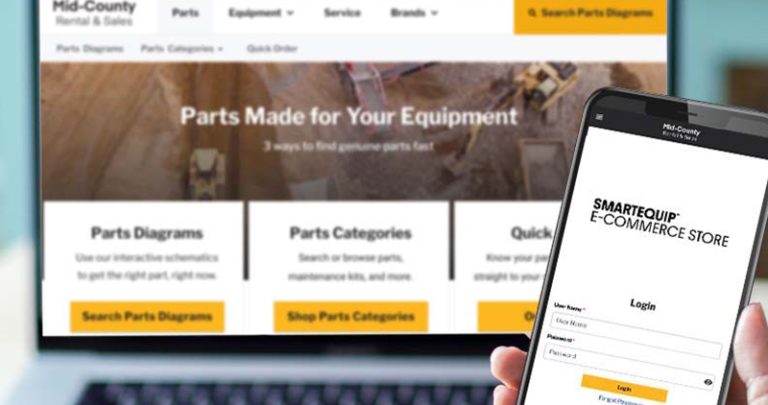

The “Internet of Things”, or IoT, will drive this. Remote diagnostics, in particular, will help identify needed parts and resources before a technician ever goes out into the field. SmartEquip’s role in this is continued help for equipment owners to identify and source parts faster and connect the dots through a 20+ year cultivated network of manufacturers and suppliers.

The result: more uptime and greater productivity through technology.

Extending Life Cycles

Remember when we started emerging from the great recession just a few years ago, and we all talked about finally replacing equipment that we had let work in our fleets longer than we typically would have? That will be another unintended consequence of our current supply chain issues.

What does that mean? Smarter fleet management, proactive/preventive maintenance and parts sourcing will be needed – helping equipment owners keep that asset working longer than they may have originally planned before transitioning to the next generation of equipment.

Right now – the used equipment market is such that owners are extending their use past when typical retirement or turn out onto the secondary market. In turn, this is not going to hurt its retained/residual value much. Regardless, there is still a solid return on that investment.

Riding the Supply Chain

The supply chain issue is not dissipating, and there are no fixes that will ease immediate needs. We wrote further on this topic in January. Long lead times and ordering challenges for equipment owners will continue for the foreseeable future.

What does this mean for operations? Getting by with current equipment and extending lifespans, proactively ordering equipment ahead of when it’s needed, and finding alternative solutions to get the job done. Not only does this affect used equipment availability, but it also plays an important role in equipment rental and auctions, as will used equipment availability and equipment auctions.

The Continued Trust in Rental

Rental is increasingly trusted for sourcing equipment – and the logic makes sense.

For the contractor: someone else manages the owning and operating costs of the asset. You simply rent it as needed and pass that cost along to the job.

For the equipment dealer or rental business: you are providing the industry a valuable service that is in high demand and turning a good profit in doing so. And as an added bonus for the equipment dealer who rents: future/prospective customers try out newer equipment on a rental contract to whet their appetites for a potential future purchase. Everyone wins – and controlling the upkeep and maintenance of that asset is easier than ever.

Electrification

It is undeniable — electrification was the buzzword of CONEXPO 2020, and there’s every sign that it will be the headline of the 2023 show as well. Important to know and realize that electrification is not for everyone. Most solutions introduced now require daily/regular charging via special charging apparatus — so it’s not yet entirely practical for many rural and large jobsites where equipment is not returned to a shop overnight and there’s no charging infrastructure nearby.

Having said that: municipalities, government agencies, utilities and contractors incentivized to use electric equipment are driving a real demand – and manufacturers are more than happy to engage in that arms race. Electrification will not take over the industry, but it will become increasingly more practical as the technology improves, becomes more accessible, and the price of diesel continues to increase.

Precision Technology as a Margin Fighter and Workforce Support

Competition is tough, and it’s getting harder and harder to wildly underbid someone to get the work without there being consequences.

Contractors who bid tightly, win, and still turn a solid profit will be the ones who position themselves for long-term success and sustainable growth. Precision earthmoving technology – machine control or grade control (depending on which nomenclature or manufacturer you prefer) — makes it possible to complete work in a shorter period of time and with less wear and tear on equipment. That drives down two significant total cost of ownership factors over the course of a single job.

These technologies are also getting easier to use every day and drive real improvements. Paired with the right business tools in place, the competition can become even tougher. So as we continue to struggle as an industry to attract new and young talent, these technologies can significantly shorten that learning curve.